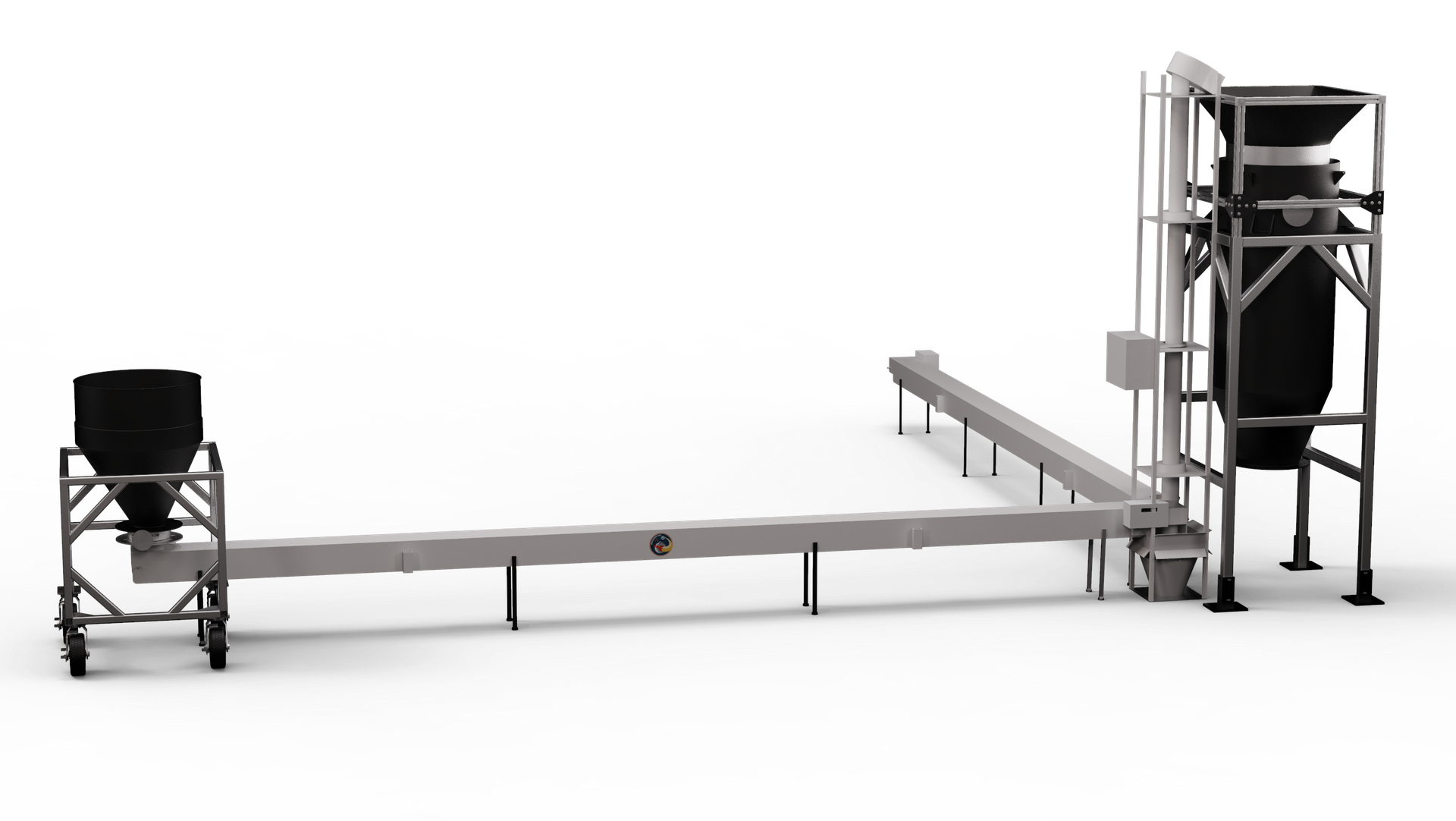

The transport system designed by Spaceship EAC addresses the difficulties of transporting regolith under lunar conditions and the requirements given by the CSM. This device consists of a tube with a fixed screw and scoops attached to the lower end. By rotating the tube, the friction with the particles, combined with the inner screw, propels the regolith upwards while the scoops push the regolith into the tube.

The system presented in this text aims to fill knowledge gaps in regolith transport under lunar

conditions with an innovative approach that takes advantage of the reduced gravity and a modular

approach that allows the creation of a network with a central node, where the vertical transport is executed.

created with

Website Builder Software .